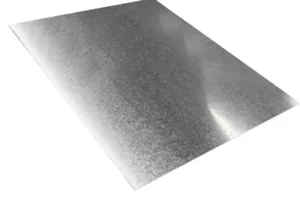

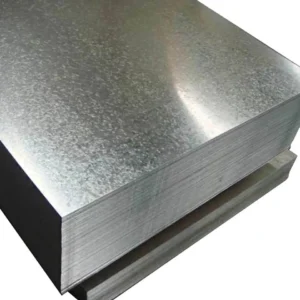

The DX51D+Z is a high-quality hot-dip galvanized steel sheet, expertly crafted to offer exceptional rust and corrosion resistance. This steel undergoes a hot-dip galvanizing process, where it’s coated with a robust layer of zinc to protect the cold-rolled substrate. Our DX51D+Z galvanized sheet is available in various zinc coating weights, including standard 80g/m² and high zinc coatings of 140g/m² and 275g/m², tailored for applications requiring enhanced durability. This zinc layer not only extends the sheet’s lifespan but also provides a polished, visually appealing finish. Ideal for construction, automotive, and industrial uses, the DX51D+Z galvanized steel is designed to withstand harsh environments while maintaining superior structural integrity.

Product Specification

| Type | DX51D+Z Galvanized Steel Sheet |

| Grade | DX51D+Z/1.0226 |

| Length | As Request |

| Material | Steel |

| Shape | Retangular |

| Thickness of Sheet | 0.13-3.0mm |

| MOQ | 10 Ton |

| Zn coating | 0.13-0.8 mm (30-150 g/m2) <br> 0.8-1.5 mm (30-180 g/m2) <br> 1.5-6.0 mm (30-275 g/m2) |

| Surface Treatment | Galvanized |

| Technology | Cold Rolled/Hot Rolled |

| Feature | Durable, Rust and Corrosion Resistance |

| Test | ISO /SGS |

| Place of Origin | China |

| Delivery Time | 10-35 Days |

| Packing | Standard Seaworthy Packing |

DX51D+Z is a hot-dip galvanized steel sheet. The substrate is a cold-rolled steel sheet, and a layer of zinc is evenly coated on its surface through the hot-dip galvanizing process to achieve excellent anti-corrosion performance. The thickness of the hot-dip galvanized layer usually varies according to different application requirements. The conventional galvanizing amount is 80g/㎡, while the high zinc layer products of 140g/㎡ and 275g/㎡ can provide stronger protection for more severe environments. DX51D+Z galvanized sheet not only has excellent corrosion resistance, but also has excellent mechanical properties and processability. It is widely used in construction, automobiles, home appliances and other fields.

Product Details

|

PRODUCT SHOW

A–Zn Coating Layer

A–Zn Coating Layer

B-Cold-Rolled Steel Sheet

C-Zn Coating Layer

These images showcase our DX51D+Z galvanized steel sheets featuring uniform zinc coating and characteristic spangle pattern. The display demonstrates various product stages, from stacked sheets to production processing. Each sheet exhibits consistent surface quality, precise dimensional control, and bright finish, highlighting our professional manufacturing standards and superior galvanization process.

|Surface Treatment

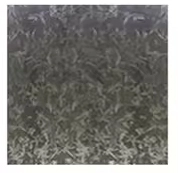

Our DX51D+Z galvanized steel sheets are available in four distinct spangle finishes, each designed for specific applications:

Large Spangles:Distinctive crystalline pattern|Traditional galvanized appearance|Ideal for construction applications

Regular Spangles:Balanced crystal size|Standard industrial finish|Versatile usage pattern

Small Spangles:Fine crystalline structure|Enhanced surface uniformity|Preferred for forming applications

Zero Spangles:Smooth, minimized crystal pattern|Superior painting surface|Perfect for architectural applications

Each surface finish undergoes strict quality control to ensure consistent zinc coating adhesion and uniform appearance. The spangle size selection depends on the end-use requirements and aesthetic preferences.

|Application

Galvanized sheets are among the construction materials and are much in use in modern construction for building infrastructure and industrial buildings. The zinc coating prevents any reaction between the surface and the air, thus providing anti-corrosion characteristics that add to the durability; therefore, galvanized sheets are used in roof panels, water pipes, drainage pipes, faucets, and ventilation systems. Galvanized sheets are also used to ‘wrap’ other metal components, improving the structural resistance noted in large building structures to harsh weather and environments.

Galvanized sheets find application in making parts of vehicle exteriors in the automotive and motorcycle sectors. The galvanization of metal surfaces he helps protect car body structures, as well as others, from corrosion, dust, and various contaminants from environmental factors. This, in turn, prolongs the life of the vehicle and keeps up its long-term appearance. Furthermore, electro-galvanized sheets are used to produce supporting parts including sliding bars, feet, and other mechanical aspects that improve the strength and durability of the vehicle as well as the motorcycle.

Electro-galvanized sheets are widely used in consumer goods manufacturing and household products. For example, in the electronics industry, electroplating of zinc is used to provide corrosion and oxidation protection for electronic components such as screws, buttons, and circuit boards. In household product manufacturing, electro galvanizing is often used to create shiny, corrosion-resistant products such as pots, pans, dishes, and other household items.

Quick info