DX53D+Z galvanized sheet is used to manufacture various non-safety structural parts, various connecting parts and various mounting brackets for automobile bending deformation and simple stamping.

|

PRODUCT DESCRIPTION

Product Specifications:

| material | DX53D+z galvanized steel sheet |

| thickness | as per customer requirements |

| width | customizable |

| coating | zinc |

| surface finish | regular spangle or minimized spangle |

| surface treatment | galvanized |

| tensile strength | as per industry standards |

| elongation | as per industry standards |

| moq | 10 ton |

| packing | mills standard export sea worthy |

| place of origin | china |

| certification supportment | yes |

| standard | astm, aisi, gb, jis, din |

| technique | hot rolled |

| delivery time | 10-35 days |

| application | construction, manufacturing, automobile, machinery |

| hardness | full hard |

| special use | cutting tools, measuring tools, cutters in common steel, high-strength steel plate, wear resistant steel, silicon steel |

The DX53D galvanized steel sheet is a premium-grade, soft hot-dip galvanized steel known for its exceptional formability and versatility. Ideal for deep drawing and bending applications, this steel sheet offers reliable mechanical properties characterized by its yield strength, tensile strength, and minimum elongation values. This balance of flexibility and strength makes DX53D suitable for intricate forming processes without compromising durability.

|

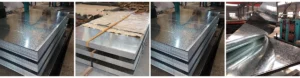

PRODUCT SHOW

Images present Galvanized Steel Sheet Supplier DX53D Hot Dipped Gi Sheet product at various angles. Steel sheets are stacked neatly to focus on the unity in their appearance and the consistent quality throughout. Shiny metallic surface reveals hot dippings of coated zinc. The sheet looks sturdy and well manufactured ready to use for several applications in construction, manufacturing, automotive, and machinery industries.

|Application

DX53D HOT-DIP GALVANIZED STEEL PLATE APPLICATION

The Hot Dipped Galvanized DX53D Steel Sheet is designed to meet a wide range of application needs, including general use, roofing, building exterior panels, structural support, wall panels, and deep drawing requirements. During production, the steel sheet is immersed in a bath of molten zinc, creating a robust zinc coating that provides enhanced corrosion resistance and durability.

|

DX53D GI Sheet Chemical Composition

| Element | Composition(%) |

| Carbon (C) | ≤0.12 |

| Silicon (Si) | ≤0.50 |

| Manganese (Mn) | ≤0.60 |

| Phosphorus (P) | ≤0.10 |

| Sulfur (S) | ≤0.045 |

| Titanium(Ti) | ≤0.30 |

|

Surface Treatment

Shunbei’s Galvanized Steel Sheet Supplier DX53D Hot Dipped Gi Sheet offers four distinct surface treatment options, each designed to cater to specific application requirements and aesthetic preferences.

Large Spangles: As shown in the first image, large spangles feature prominent, flowery zinc patterns. This finish offers excellent corrosion resistance and a decorative touch, ideal for visually appealing applications.

Regular Spangles: The second image shows regular spangles with uniform, moderate zinc patterns. This finish balances corrosion protection and aesthetics, making it versatile for various uses.

Small Spangles: Illustrated in the third image, small spangles have refined, subtle zinc patterns. They create a smooth surface, suitable for sleek applications while maintaining corrosion resistance.

Zero Spangles: The fourth image depicts zero spangles, offering a smooth, uniform appearance without visible zinc patterns. This finish is perfect for high-aesthetic applications like architecture or automotive components.

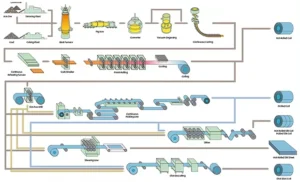

Production Process

|

Production Process

Quick info