10 TON

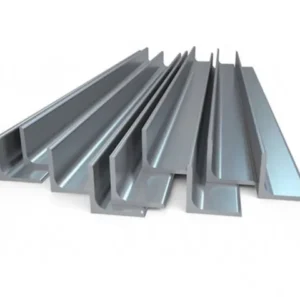

316 stainless steel angles offer excellent corrosion resistance and high-temperature strength, making them particularly suitable for demanding environments such as marine, chemical, food processing, and medical equipment. Available in a variety of sizes, with custom lengths and surface finishes, they meet diverse engineering needs.

316 stainless steel angles are made from AISI 316 and are classified as equal-leg angles. The addition of molybdenum (Mo) ensures excellent corrosion resistance and mechanical properties in chloride environments and at high temperatures. Their high strength and excellent workability make them widely used in marine engineering, chemical processing, food processing, medical equipment, and high-end architectural decoration.

Material: AISI 316 / UNS S31600 / 1.4401

Type: Equal Leg Angle

Dimension Range:

Side Length: 20mm to 100mm (Common: 25mm, 40mm, 50mm, 75mm, 100mm)

Thickness: 3mm to 10mm

Length: 6m, 9m, 12m, or custom-made

Surface Finish: Mill Finish, Pickled, Polished (Optional)

Standards: ASTM A276, A484, JIS G4303, GB/T 1220

Packaging: Standard seaworthy packaging, bundled, palletized, or in bulk

✅ Excellent corrosion resistance: Particularly suitable for chloride environments, such as those in the marine and chemical industries

✅ Excellent high-temperature performance: Maintains strength and stability in high-temperature environments

✅ Excellent processability: Easy to weld, cut, and form

✅ Available in a variety of sizes: Meet diverse engineering and custom needs

Quick info