Product Description

DX56D+Z galvanized steel sheet is created through an advanced hot-dip galvanizing process, where a steel sheet is submerged in molten zinc to form a protective zinc layer on its surface. This continuous process ensures a uniformly coated, high-quality galvanized steel sheet with excellent durability.For enhanced performance, our alloyed galvanized steel sheet undergoes an additional step: after the initial zinc coating, it is heated to approximately 500°C, allowing the formation of a zinc-iron alloy layer. This alloy layer significantly improves the coating’s adhesion and the sheet’s weldability, making it a reliable choice for demanding applications.

| Zinc Coating | Z30-Z275g/m2 |

| Spangle | Smooth |

| MOQ | 1 TON |

| Thickness | 2.0-3.0mm(HR) |

|

Processing Service

|

Welding/Punching/Cutting/Bending/Decoiling

|

| Surface | Polished |

| Technique | Hot dipped |

|

Place of Origin

|

MADE IN CHINA |

|

DX56D Chemical Composition

| Element | Composition (%) |

| Carbon(C) | ≤0.12 |

| Silicon (Si) | ≤0.50 |

| Manganese (Mn) | ≤0.60 |

| Phosphorus(P) | ≤0.1 |

| Sulfur (S) | ≤0.045 |

| Alt | ≤0.3 |

|

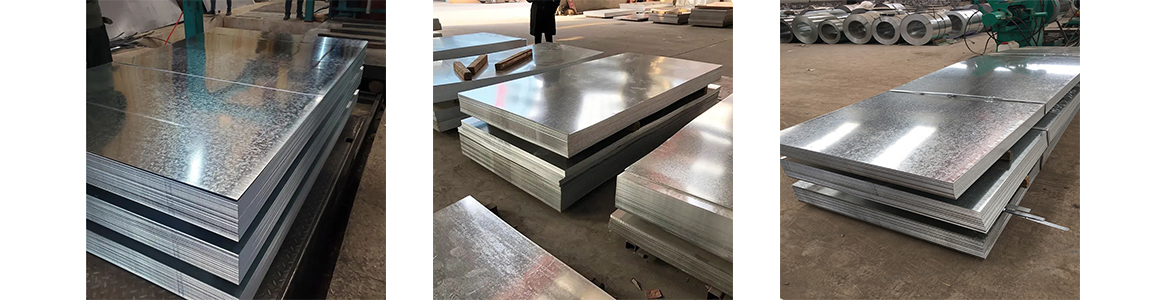

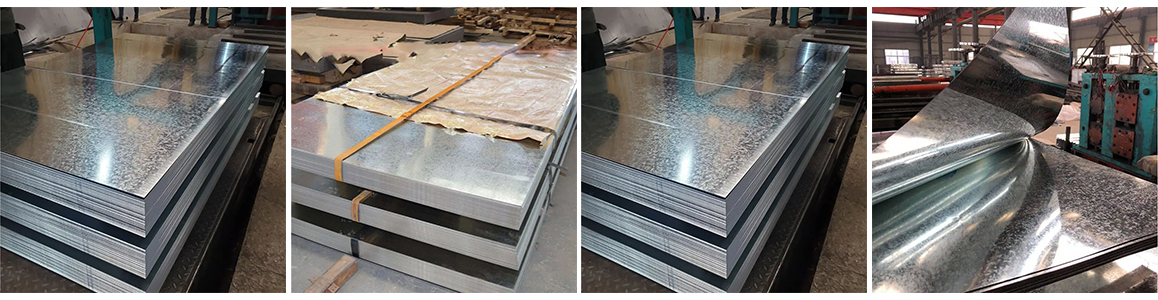

Product Show

Application

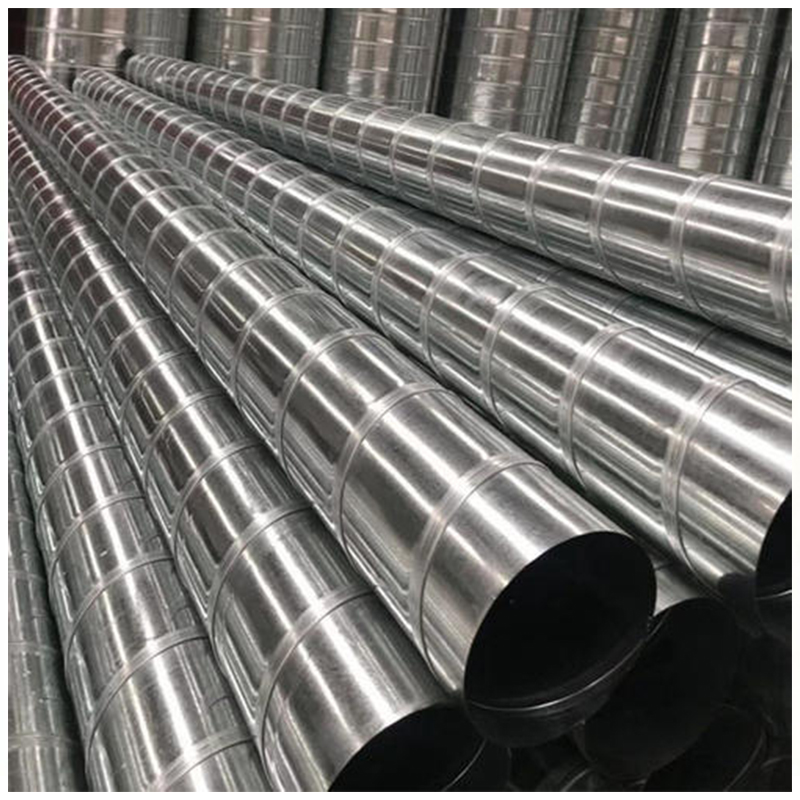

“DX56D galvanized sheet” can be used to manufacture various types of pipelines, such as water supply pipelines, oil pipelines, natural gas pipelines, etc. Its corrosion resistance can effectively extend the service life of pipelines.

After being pressed by abrasive tools, “DX56D+Z galvanized plate” can be used to make Gi corrugated sheet , which are widely used in building roofs, walls, isolation boards, and other products. This galvanized sheet has excellent waterproofing and durability properties and can effectively protect buildings from moisture intrusion and environmental corrosion. Its corrugated design also adds to the structural strength and aesthetics of the building.

DX56D+z galvanised sheet is an excellent metal material that can be used to manufacture various types of containers, such as storage tanks, barrels, etc. Oil tanks are made of DX56D galvanized sheets. Due to the corrosion resistance of the galvanized layer, it can effectively protect the contents inside the container from the external environment. The protective layer formed by the zinc coating on the surface can prevent the erosion of oxygen, moisture, and other corrosive substances, thus extending the service life of the container and ensuring the safety of stored items. Therefore, in the industrial field, DX56D galvanized sheet containers can provide reliable anti-corrosion protection to ensure the quality and stability of stored items.

Production Process

THE PRODUCTION PROCESS OF DX56D GALVANIZED SHEET

|

Common coating methods

ELECTRO

COLD-DIPPED

HOT DIP GALVANIZING PRODUCTION PROCESS

Quick info